RNA Automation

| |

| Industry | Robotics, Industrial Automation, manufacturing |

|---|---|

| Founded | 1986 |

| Headquarters | Birmingham, United Kingdom |

Area served | Worldwide |

| Products | Bowl feeder, Visual inspection, Machine vision, Robotics, Vision Guided Robotic Systems, Industrial automation |

| Website | http://www.rnaautomation.com/ |

RNA Automation, a member of Rhein-Nadel Automation, was established in Birmingham UK in 1986, and has progressed into becoming the major supplier of parts handling equipment in the UK. The company operates in the area of specialised automation engineering, providing automatic parts handling equipment for high volume production in the cosmetics, pharmaceutical, electronics, food and metal working industries, with seven manufacturing facilities across Europe and North America and a network of sales and service outlets across the globe.[1]

Group history

Founded in 1972, Rhein-Nadel Automation is the market leader throughout Europe and operates worldwide in parts handling technology. Rhein-Nadel Automation is a member of the Rheinnadel Group, which has been based since 1898 in the town of Aachen, Germany. Rhein-Nadel Automation have four manufacturing sites in Germany and individual manufacturing plants in the UK, Spain and Switzerland, together with a world-wide, decentralised distribution and service network with 28 subsidiaries.[2]

1898 The 'Rheinische needle factories AG' was founded in Aachen. Production and sales of sewing, plug and pins as well as home sewing machine needles.

1911-1939 The company's expansion to 14 divisions (different needle types, zippers, motorcycle rims, hair cutting machines, packaging tapes, etc.).

1945 Change of name to 'Rheinische GmbH needle factories'.

1955 Takeover of the company by the brothers Horst and Herbert Pavel, after the purchase of new investments.

1968 The department of the needle factory, so far only responsible for the internal construction of operating material and machines, trades under the name Rheinnadel Maschinenbau and begins working for external customers.

1972 Rheinnadel Maschinenbau now also uses the firm name Rhein-Nadel Automation GmbH and concentrates exclusively on the area of Feeding Technology.

1980-1989 Rhein-Nadel Automation expands. The permanent establishment in Ergolding and the subsidiaries in Switzerland and Great Britain are founded.

1990-1999 Rhein-Nadel Automation continues to grow. The Spanish company Vibrant S.A. is purchased.

2004 The Rheinnadel Group concentrates its activities on the area of Automation. RNA broadens its range with the components and continues to extend its development capacities.

2004-2009 Development of new markets in East Asia and Eastern Europe.

2011 RNA expanded and founded the subsidiary PSA in Schwabisch Hall

Products and technology

RNA supplies a wide range of advanced automation systems and services. Its products can be divided into the following categories: Assembly machines, robotic systems, vision inspection systems and automated feeding and handling systems.[3]

RNA automated feeding and handling systems include vibratory bowl feeders, centrifugal feeders, linear and conveyor feed systems, hopper elevator systems and step feeder systems.[3]

RNA vision inspection systems include MK360 glass disc vision inspection system, vision systems for quality control checks, OCR and batch sorting applications, tablet and capsule inspection systems and vision system integration services. The systems are developed to meet high-speed quality control requirements for 100% inspection.[3]

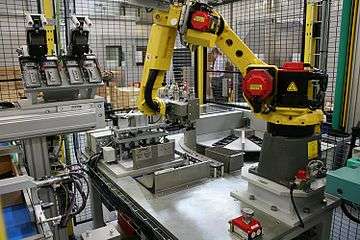

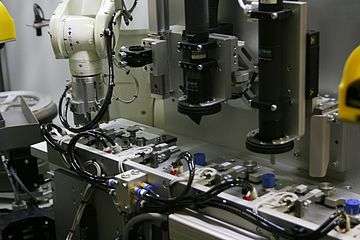

RNA robotic systems automate clients' production lines where small batch runs and sensitive, difficult components have normally been impossible to automate. All systems have a robotic arm for handling and manipulating the product, a camera system and share the same PC based control system and in most cases integrated with a standard robot controller.[3]

RNA assembly machines include special purpose machinery, automation production systems and industrial automated systems.[3]

A RNA Flip Top Cap Closing System[4]

A RNA Flip Top Cap Closing System[4] A RNA Robotic Loading and Test System[5]

A RNA Robotic Loading and Test System[5] A RNA Laser Drill Vision Inspection System[6]

A RNA Laser Drill Vision Inspection System[6] A RNA Salad Loading and Handling System[7]

A RNA Salad Loading and Handling System[7]

Partnerships

Universal Robots RNA are agents in the UK for the Universal Robots range of collaborative robots. Universal robots develop light and inexpensive collaborative robots that are easy to install and programme. The robots can operate without safety shielding for most applications and with an average payback period of as little as six months. They can be quickly reprogrammed to handle other tasks, meeting most of the requirements of industrial enterprises and production companies.[8]

Asyril SA RNA and Asyril cooperate in the development and sales of Flexible Part Feeding Systems and Vibration Platforms. Asyril’s award-winning series of Asycube flexible feeders offers high performance part feeding, pre-orientation and optimal surface distribution of bulk parts and components. Asyril’s 3-axis vibration technology can handle bulk parts of any geometry and allows for extremely gentle part feeding of even the most complex part shapes and delicate materials.[8]

Italplant RNA are agents in the UK & Ireland for the Italplant range of rotary and precision link conveyor index units. From a small table mounted rotary indexer to a 54” precision link conveyor Italplant have the expertise knowledge and experience to provide a solution for your indexing needs. All Italplant Indexers are compatible with other brands of index units and can be supplied with a dial plate mounted and machined to customer’s exact specifications. Where the project requires an inline system Italplant specialise in Precision Link conveyors for high accuracy stations such as laser marking, pad printing and vision inspection applications.[8]

RoboMat RNA the sole agents in the UK & Ireland for the RoboMat range of palletizing systems. RoboMat have over 25 years experience of automatic stand-alone palletizing systems for picking and placing components from preformed trays. RoboMat palletizing systems are used for sensitive and difficult components in industries such as cosmetics, pharmaceuticals, jewelleries and sintered metals, offering simplified modular designs for a wide variety of applications.[8]

Operations

Rhein-Nadel Automation have four manufacturing sites in Germany and individual manufacturing plants in the UK, Spain and Switzerland, together with a world-wide, decentralised distribution and service network with 28 subsidiaries.

See also

- Industrial robot

- Bowl feeder

- Visual inspection

- Vision Guided Robotic Systems

- Industrial automation

- Assembly machines

External links

- RNA Automation website

- Rhein-Nadel Automation

- Universal Robots website

- Asyril SA website

- Italplant website

- RoboMat website

References

- ↑ "Company Profile".

- ↑ "Rhein-nadel Group - website".

- 1 2 3 4 5 "RNA's Products - Profile".

- ↑ "Case Study RNA flip top caps closing system".

- ↑ "Case Study RNA Robotic Loading and Test System".

- ↑ "Case Study RNA Laser Drill Vision Inspection System".

- ↑ "Case Study RNA Salad Loading and Handling System".

- 1 2 3 4 "RNA's Partnerships - Profile".