Carbyl sulfate

| |

| Names | |

|---|---|

| IUPAC name

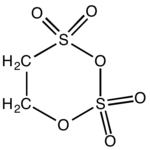

1,3,2,4-Dioxadithiane 2,2,4,4-tetraoxide | |

| Identifiers | |

| 503-41-3 | |

| 3D model (Jmol) | Interactive image |

| ChemSpider | 61459 |

| ECHA InfoCard | 100.007.244 |

| PubChem | 68151 |

| |

| |

| Properties | |

| C2H4O6S2 | |

| Molar mass | 188.17 g·mol−1 |

| Appearance | White solid |

| Melting point | 107.5–109 °C (225.5–228.2 °F; 380.6–382.1 K) |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

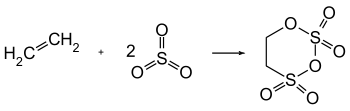

Carbyl sulfate is an organosulfur compound. The white solid is the product of the reaction of sulfur trioxide and ethene. It is used in preparation of some dyes and other organosulfur compounds.[1]

History

Regnault[2] and Heinrich Gustav Magnus[3][4] reported first in the years 1838 to 1839 on the compound as reaction product of anhydrous ethanol and anhydrous sulfuric acid.

Manufacturing

Carbyl sulfate is produced in the highly exothermic (about 800 kcal/kg) reaction of ethene and sulfur in the vapor phase in nearly quantitative yield.[5][6]

In industrial production dry ethene and gaseous sulfur trioxide are reacted in a mixing ratio of 1:2.2 to 1.2,4 at 115 to 140 °C in one or two series-connected tube reactors. Liquid carbyl sulfate is continuously removed from the bottom of the reactor. The reaction conversion is already in the first reactor at least 80%.[6] Also disulfuric acid or chlorosulfuric acid can be used as a sulfonating agent (replacing sulfur trioxide); instead of ethene ethene-forming agents can be used, e.g. ethanol or diethyl ether.[5]

Properties

Carbyl sulfate is a colorless, crystalline, hygroscopic substance with the pungent smell of sulfur dioxide and high reactivity, which may decompose explosively when heated above 170 °C. The product of industrial processes is a water-clear liquid which has - in accordance with D.S. Breslow[5] (107.5 to 109 °C) - a melting range from 102 to 108 °C. The 1839[4] stated melting point of about 80 °C is resulting from adhering sulfur trioxide.[5] Because of its unpleasant properties carbyl sulfate is difficult to handle and is usually not isolated but further processed to give secondary products.

Reactions and use

As a cyclic sulfate ester, it is an alkylating agent. Hydrolysis affords ethionic acid:

- C2H4(SO3)2 + H2O → HOSO3C2H4SO3H

Ethionic acid undergoes further hydrolysis to isethionic acid:

- HOSO3C2H4SO3H + H2O → HOC2H4SO3H + H2SO4

Carbyl sulfate is used as precursor for vinylsulfonic acid and sodium vinyl sulfonate, which are important activated alkenes and are used e. g. as anionic comonomers. A number of functional compounds with a variety of applications are available by nucleophilic addition at the activated double bond of the vinyl sulfonic acid and its derivatives.[7]

References

- ↑ Kosswig, Kurt (2000). "Sulfonic Acids, Aliphatic". Ullmann's Encyclopedia of Industrial Chemistry. Wiley-VCH. doi:10.1002/14356007.a25_503. ISBN 3-527-30673-0.

- ↑ Regnault, Ann., 25, 32 (1838), Ueber die Einwirkung der wasserfreien Schwefelsäure auf Doppeltkohlenwasserstoff, DOI:10.1002/jlac.18380250103.

- ↑ Magnus, Ann., 31, 249 (1839) und G. Magnus, "Ueber das Carbylsulfat und die Aethionsäure", Pogg. Ann. ( = Annalen der Physik), XLVII, 609 (1839), DOI:10.1002/jlac.18390320310.

- 1 2 "Zur Erinnerung an Gustav Magnus". Nach einem am 14. December 1870 in der General-Versammlung der Deutschen Chemischen Gesellschaft zu Berlin gehaltenen Vortrage August Wilhelm Hofmann s, Berlin, Ferd. Dümmler's Verlagsbuchhandlung, 1871 (S. 32).

- 1 2 3 4 David S. Breslow; Robert R. Hough (1957), "The Synthesis of Sodium Ethylenesulfonate from Ethylene" (in German), Journal of the American Chemical Society 79 (18): pp. 5000–5002, doi:10.1021/ja01575a046

- 1 2 DE 2509738 "Verfahren zur Herstellung von Carbylsulfat." Inventor: Rudolf Irnich, Rolf Schneider

- ↑ H. Distler (1965-04-07). "Zur Chemie der Vinylsulfonsäure". Angewandte Chemie. 77 (7): 291–302. doi:10.1002/ange.19650770704.

Further reading

- Breslow, David S.; Hough, Robert R. (1957). "Synthesis of sodium ethylenesulfonate from ethylene". Journal of the American Chemical Society. 79: 5000–5002. doi:10.1021/ja01575a046.